Our products: vertical turbine pump, vertical wet pit pump, vertical oil sump pump, vertical condensation pump, right Angle gearbox

source:Vertical Turbine Pump Manufacturer and Vertical Suspension Pump Prices Provider

DATE:2024/11/7 15:56:43

Visits:

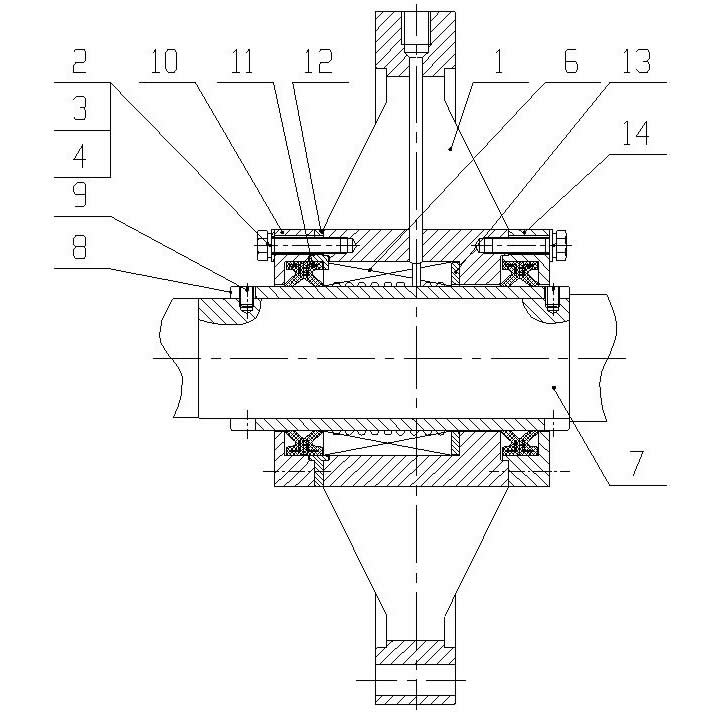

The sealing device of the suspended semi submersible vertical turbine pump is equipped with a shaft sleeve between the pump shaft and the bearing seat. The left and right ends of the shaft sleeve are fixed to the pump shaft by several evenly distributed fastening screws on the outer cylindrical surface; The bolts pass through the lower cover in sequence and are fixed to the left end face of the bearing seat with a compression washer. A sliding bearing is provided between the bearing seat and the shaft sleeve, and two K-rings are arranged back-to-back between the left end of the sliding bearing and the stepped surface of the lower cover; A bearing washer is installed between the right end of the sliding bearing and the stepped surface of the inner hole of the bearing seat; The upper cover is fixed to the right end face of the bearing seat by bolts, and there are two K-rings between the upper cover and the shaft sleeve, which are arranged back-to-back; The K-ring is made of PE wear-resistant and corrosion-resistant material. This technical method has good sealing performance, improves the stability of the suspended semi submersible vertical turbine pump, enhances the wear resistance of the pump shaft and sliding bearings, extends the service life of the suspended semi submersible vertical turbine pump, reduces the material input of the pump, and lowers production costs.

Technical requirements: 1. A sealing device for a new type of suspended semi submersible vertical turbine pump, comprising an intermediate bearing frame (1), bolts (2), a pump shaft (7), and an upper cover plate (14). The center of the intermediate bearing frame (1) is provided with a bearing seat, characterized in that a shaft sleeve (8) is provided between the pump shaft (7) and the bearing seat, and the left and right ends of the shaft sleeve (8) are fixed to the pump shaft (7) by several fastening screws (9) evenly distributed on the outer cylindrical surface; The bolt (2) passes through the lower cover (10) and the compression washer (12) in sequence, and is fixed on the left end face of the bearing seat. A sliding bearing (6) is provided between the bearing seat and the shaft sleeve (8); The left end of the sliding bearing (6) is equipped with a stopper, and the inner teeth of the compression washer (12) are installed inside the stopper; There are two K-rings (11) arranged back-to-back between the left end of the sliding bearing (6) and the stepped surface of the lower cover (10); A bearing washer (13) is provided between the right end of the sliding bearing (6) and the stepped surface of the inner hole of the bearing seat.

Copyright © 2008-2024 Hunan Perfect Industry Co.,Ltd All Rights Reserved.

+8613974960765

Wechat QR code